Raw materials with moisture content of ≤2% and particle size of ≤15mm (which can be cheap and easily got from stone chips and rice stones) are reasonably and efficiently processed by the VU aggregate optimization system, reasonable output gradation, round particle shape,finished sand with controllable powder content, as well as dry and clean, high-value-added stone powder that can be recycled and reused (the applicable range is determined according to the raw material).

Cheap tailings, such as construction waste, stone chips and pea stone.

Artificial sand making for concrete mixing stations, dry mortar, cement factory, mines, large -scale construction projects, etc.

| Model | VU-100 | VU-150 | VU-300 |

| Feeding size(mm) | 0-25 |

0-25

|

0-25 |

| Feeding capacity(t/h) | 80-100 | 125.150 | 240-300 |

| Capacity(t/h) | 70-90 | 110-135 | 220-270 |

| Stone powder content(%) | 3- 15% |

3- 15%

|

3- 15% |

| Power(kW) | ≈681 | ≈996 | ≈1974 |

| Dimension(m)L×W×H | 29×8×26 | - | 28×15×24 |

| Main equipment | VU special sand making machine | ||

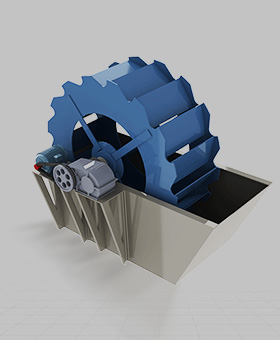

| Classifier | |||

| Dust Catcher | |||

| Fine sand recovery system | |||

| Bucket elevator | |||

| Accessory equipment | Humidifying mixer | ||

| Belt conveyor | |||

| Connecting pipes | |||

| Steel frame for the sand making tower | |||

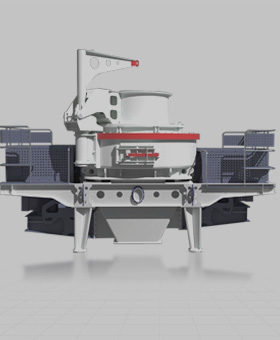

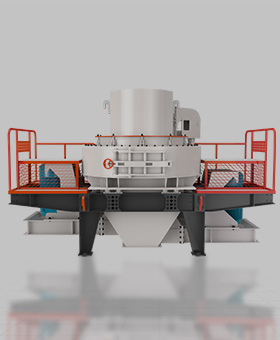

| Model |

VuS301

|

VuS501

|

|||

| Sand Making |

Aggregates Shaping & Sand Making

|

Sand Making |

Aggregates Shaping & Sand Making

|

||

|

Main machine

|

VSI6X1040 | VSI6X1263 | |||

|

Feeding size(mm)

|

0-40 | 0-40 | |||

|

Max feeding capacity(t/h)

|

100 | 300 | 150 | 550 | |

|

Powder content (%)

|

3-15% | 3-15% | |||

|

Power(kW)

|

≈622 | ≈966 | |||

|

Dimension L×W×H(m)

|

21×8×27.5 | 21×10×30.2 | |||

| Main Equipment |

VUS type vertical shaft impact crusher

|

||||

| Stone powder separating device | |||||

| Environmentally friendly synchronous sorting screen | |||||

| Fine sand recovery system | |||||

| Dust Catcher | |||||

| Bucket elevator | |||||

| Accessory Equipment |

Humidifying mixer

|

||||

| Connecting pipes | |||||

| Belt conveyor | |||||

| Steel frame for the sand making tower | |||||